Standing Strong

The Elesa+Ganter portfolio offers an extensive selection of levelling feet, including machine feet, articulated feet, leveling feet, and corrosion-resistant stainless steel options. This diverse range continues to expand because, upon closer inspection, the requirements for these essential components are far from simple.

During the early stages of engineering, developers often overlook the importance of leveling feet. However, these feet play a crucial role in supporting the entire load of the structures they are installed beneath. So, what qualities must levelling feet possess to withstand the harsh conditions of industrial applications?

First and foremost, they must provide stability, securely handle various loads, offer precise adjustability, and boast a long service life. Moreover, they should visually demonstrate these qualities to assure users of their reliability.

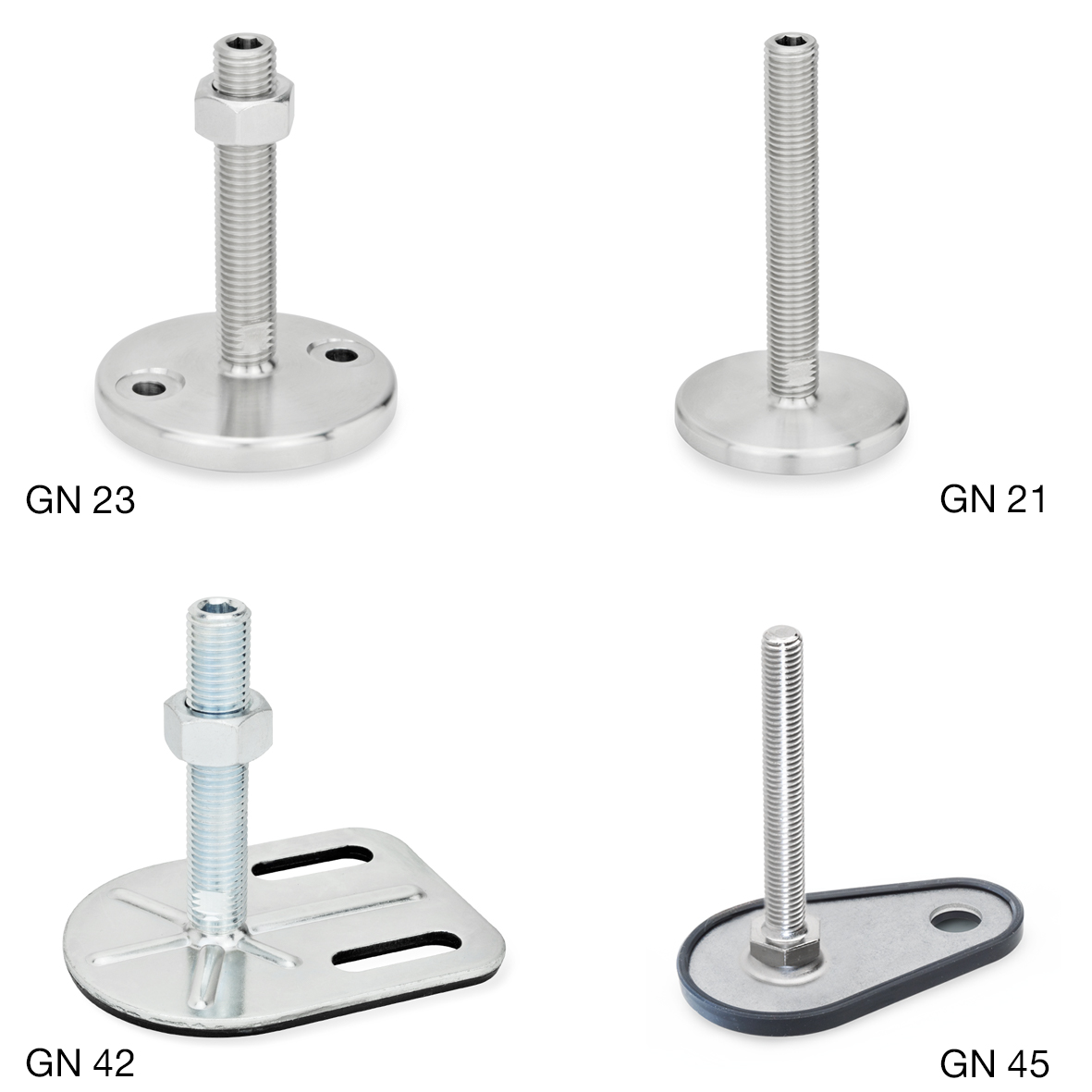

One prime example of this attention to detail is the leveling foot GN 21 from the Elesa+Ganter range. Made entirely of stainless steel, its plate is expertly machined from solid material, resulting in a refined surface. The version with mounting holes in the plate is designated GN 23.

For universal use, the GN 42 and GN 43 “duckfoot” types are ideal. They come with tolerance-friendly slots and reinforced plates to withstand heavy loads. Their peculiar name comes from the half round, half rectangular shape. Depending on the standard, they are crafted from either galvanized steel or AISI 304 quality stainless steel, with an optional vulcanized layer on the underside of the plate.

In contrast, the GN 44 and GN 45 feet are specifically designed for highly corrosive environments, making use of stainless steel AISI 316 L. They feature a droplet-shaped support surface with a fastening hole or a proven round plate shape, both optionally available with rubber underlay.

The Elesa+Ganter range offers an abundance of options to fulfill various requirements. Alongside a variety of plate shapes, the spindles can be selected with or without locknuts, along with adjustment sleeves for thread coverage. Different drive types and internal thread options are also available, each crafted from various high-quality materials.

More information on these Elesa+Ganter standard parts and others can be found on OIC’s Levelling Element section of its website.