Features

Thanks to the property of the SUPER-technopolymer stem, high rigidity and mechanical resistance are obtained in addition to natural resistance to corrosion.

Have been designed to damp vibrations, shocks and noises produced by moving bodies or non-balanced vibrating masses of equipment and machines which can cause:

- malfunctioning and reduction of the machine lifespan and/or of the adjacent ones;

- damage to operator’s health;

Order information

The levelling feet are supplied unassembled to make carriage and storage easier. The components (base and stem) are supplied in separate packing: less volume taken and better protection from scratches and dirt.

To order bases and stems separately, see:

- table of possible combinations Bases/Stems

Technical data and guidelines for the choice

The maximum static load value shown in the table indicates the static load for a specific load of 0.4 N/mm2 to which the damping element can be subjected in order to have optimal vibration absorption.

The table shows also the values (l2) of elastic deformation with a load of max 0.6 N/mm² in case of a dynamic load.

The effectiveness of the damping depends on the ratio between the disturbance frequency of the machine and the natural frequency of the damping foot.

The natural frequency of the base depends on the material, the geometry, and the specific load [N/mm2] to which it is subjected.

The specific load is obtained by dividing the applied load by the support area of the damping element.

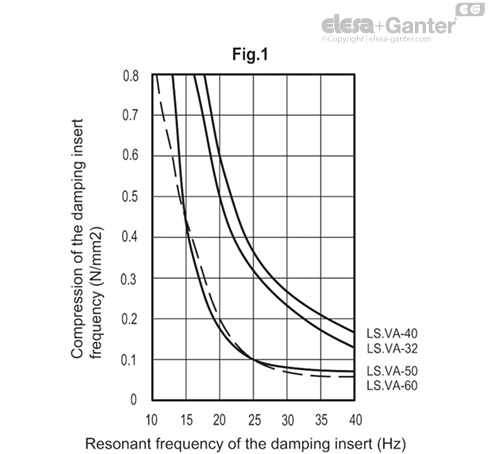

Once the specific load is known, the natural frequency of the foot can be obtained from the graph in figure 1.

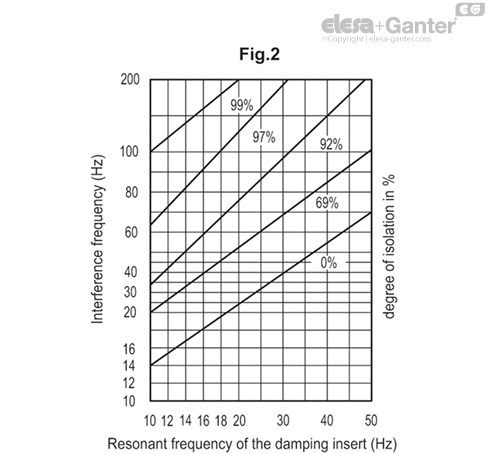

The damping starts when the ratio between the disturbance frequency of the machine and the natural frequency of the damping foot is greater than √2. The greater the difference between the interference frequency of the machine and the natural frequency of the foot, the greater the damping (see figure 2).

Example:

- Expected load on the foot = 150 N

- Specific load LS.VA-32 = 150/239 = 0.63 N/mm2

- Specific load LS.VA-40 = 150/452 = 0.33 N/mm2

- LS.VA-40 is therefore chosen as the specific load of the example is less than 0.4 N/mm2 , which is the optimal damping value.

- Entering the graph in figure 1 with a specific load of 0.33 N/mm2 we obtain a natural frequency of 26 Hz (curve LS.VA-40).

- Entering the graph in figure 2, with 26 Hz, the chosen foot will start to dampen frequencies greater than 32 Hz.

A damping of 69% is obtained for a machine frequency of 61 Hz.

A damping of 92% is obtained for a machine frequency of 85 Hz.