MPI-15

Magnetic measuring system

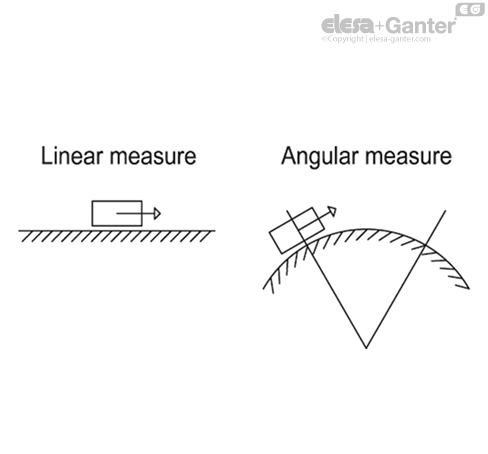

Length and angle modes

MPI-15

Magnetic measuring system

Magnetic measuring system

MPI-15

Magnetic measuring system

Magnetic measuring system

Features and applications

MPI-15 measuring system, made of a LCD multifunction display with built-in magnetic position sensor, combined with the magnetic band M-BAND-10 (to be ordered separately), is a complete system for the measurement of linear and angular displacement (with a minimum radius of 65 mm).

Characterised by an extremely easy assembly, it allows precise alignment and positioning, reducing time and machining procedures to the minimum.

- Multifunction LCD with 5 function keys.

- Absolute/ incremental mode.

- Programmable offset function.

- External battery power supply 1.5 VDC.

- Buffered memory during battery substitution.

- Accidental polarity inversion protection.

- Magnetic sensor envelope material: anodized aluminium.

For further information read the operating instructions.

| Technical data | |

|---|---|

| Battery life | 1.5 years (C-type battery) |

| Resolution(1) | 0.1 mm - 0.01 in - 0.01° |

| Precision(2) | 0.1 mm |

| Repeat accuracy(3) | 0.001 mm |

| Operating speed | max. 5 m/s |

| Self-diagnostic | battery check, sensor check, magnetic tape check |

| Programmable measuring unit | millimetres, inches, degrees (angles) |

| Working temperature | 0 ÷ 50 °C |

| Storing temperature | -20 ÷ +70 °C |

| Relative humidity | Max. 95% at 25°C without condensation |

| Protection class | IP40 whole device IP54 front side according to IEC 529 IP67 magnetic sensor |

| Interference protection | IEC 61000-4-2 |

(1) Resolution: the smallest change in length that the system is capable of displaying.

(2) Precision: the maximum deviation of the value measured by the system from the actual one.

(3) Repeat accuracy: the degree of closeness between a series of measures of the same sample, when the single measurements are carried out leaving the asurement conditions unchanged.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.