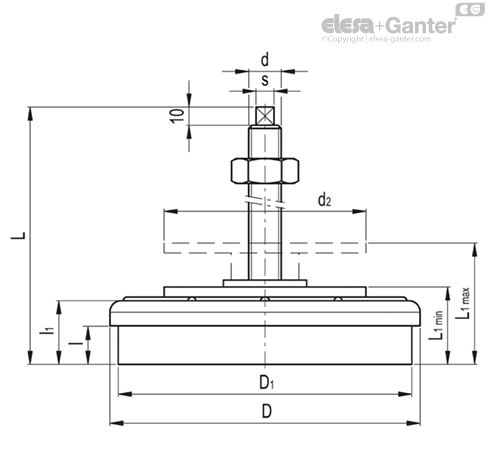

LW.A

Vibration-damping levelling feet

Steel base and stem

LW.A

Vibration-damping levelling feet

Vibration-damping levelling feet

LW.A

Vibration-damping levelling feet

Vibration-damping levelling feet

Base

Zinc-plated steel.

Damping element

NR rubber, hardness 80 Shore A, black colour, matte finish.

Levelling plate

Zinc-plated steel.

Packing ring

NBR synthetic rubber O-Ring.

Threaded stem

Zinc-plated steel, supplied not assembled.

Nut and washer

Zinc-plated steel.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.