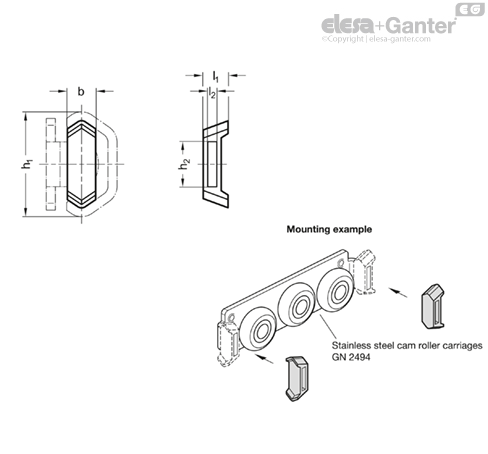

GN 2498

Wipers

for Stainless Steel Cam Roller Linear Guide Rails GN 2492

GN 2498

Wipers

Wipers

GN 2498

Wipers

Wipers

Type

- Type K: Compact design

Coding

- X: For fixed bearing guide rail

Wipers

Polyurethane (TPU)

Blue, FDA compliant

Operating temperature -20 °C to 100 °C

Wipers GN 2498 protect against dirt deposits in stainless steel cam roller linear guide rails GN 2492 and stainless steel cam rollers GN 2496.

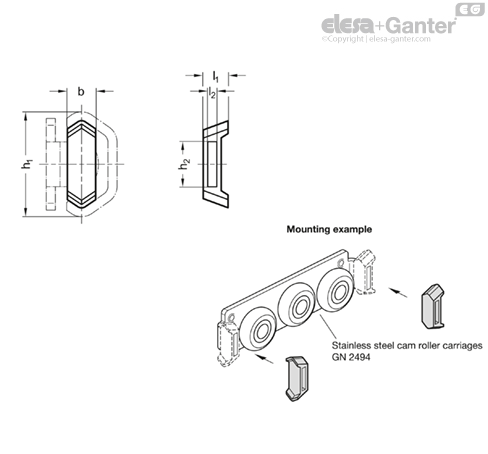

The wipers are provided as a replacement part for cam roller carriage GN 2494 to allow easy exchange in case of wear. Alternatively, they can be used on custom-built cam roller carriages. Based on the dimensions of the rectangular cutout designated for fastening them to the cam roller carriage.

The material can also be used in special environments that can be found, for example, in the pharmaceutical and food processing industries.

The wipers can be manually pushed onto the provided retaining tabs on the cam roller carriages and prepositioned. When inserting the carriage into the guide rail, check the position and adjust if necessary. The wipers will automatically assume proper alignment during operation.

The following installation information should be taken into account in the use and assembly of stainless steel linear guide rail systems.

This ensures smooth running, quiet operation, low wear, and proper function over prolonged use.

- Stainless steel linear guide rail systems are normally installed in pairs. The surrounding structure should have adequate stability, e.g. to minimize geometric errors caused by elastic deformation.

- The mounting surfaces of the linear guide rail systems (guide rails and cam roller carriages) must be level, parallel, and at right angles as well as correctly situated relative to each other. The linear limit of the runner is established by external stop elements. If several stops are used, they should be reached at the same time.

- Fastening holes should be applied in such a way that excludes twisting or warping of the stainless steel guide rails during mounting.

- After the linear guide rail systems are mounted, they must be checked to ensure smooth running. If something is wrong such as sticking or warping, the cause has to be determined and appropriately eliminated.

During assembly, all mounting slots in the guide rail and the fastening thread on the cam roller carriage must be used. This ensures that the forces resulting from the maximum load FR / FA are reliably transferred to the surrounding structure. Failure to use fastening screws reduces the load capacity accordingly.

Various screws with the appropriate threads can be used for mounting the cam roller carriages. Observe the maximum thread tightening depth „t“. In contrast, assemble the rail with ISO 7380 screws (screws with a flat semicircular head) to avoid collisions with the cam roller carriage. Screws with a head height that is the same or less are also permissible. It is generally recommended to use stainless steel screws of property class A2 or A4-70 or higher under consideration of the specified tightening torque.

Stainless steel linear guide rail systems are made up of stainless steel cam roller linear guide rails GN 2492 and stainless steel cam roller carriages GN 2494. All required components are provided unassembled in separate packages.

When delivered, the play between cam roller carriage and rail is not preset. During assembly, set the cam roller carriage as follows:

1. Make sure that the raceways and guide rollers are clean.

2. Loosen the fixing screw of the central adjustable eccentric guide roller slightly and insert the cam roller carriage into the guide rail without the wipers (see steps 4 and 6).

3. Position the roller carriage at one end of the guide rail.

4. Insert the open-end wrench between the eccentric roller and the cam roller carriage. The two centering holes on the left and right of the cam roller carriage mark the position of the running side for the two concentric and supporting rollers.

5. Turning the wrench clockwise presses the guide roller against the support raceway of the rail so that there is no play for the roller carriage. Overtightening will increase friction and reduce the service life of the item.

6. While holding the bearing pivot of the eccentric guide roller in place with the wrench, tighten the fixing screw moderately. The precise torque will be checked later.

7. Move the cam roller carriage in the guide rail and make sure that the play or slight preload is consistent across the entire length of the rail. The cam roller carriage should move easily without being overly loose or tight. Adjust if necessary.

8. Tighten the fixing screw using the torque specified in the table (observe construction height h1). Use the open-end wrench to hold the eccentric guide roller at its final angle to prevent accidental adjustments. Adhesive can also be used to fix the screw in position.

| h1 (construction height) | Torque |

| 30 | 6 Nm |

| 45 | 10 Nm |

9. Insert the wipers. Take the roller carriage out of the rail and reinsert it to check where the wipers will go. The wipers will self-align during use.

10. Spare parts:

- Stainless Steel Cam Rollers GN 2496

- Wipers GN 2498

- Open-End Wrench GN 2424.1-13-15

The maximum travel speed of the stainless steel linear guide rail systems is 1.5 m/s. The acceleration may be up to 2 m/s2. If end stops are used, the speed should be significantly reduced before reaching the stop to avoid damage.

The temperature of use of the linear guide rails is -20 °C to 100 °C. The temperature range is dictated by the wiper material. If they are not needed, the range extends from -40 °C to 100 °C (briefly 120°) since the material of the sealing discs of the cam rollers then sets the temperature range.

The maximum load capacity of a linear guide rail system corresponds to the use of two cam roller carriages and is limited by the stability of the guide rail. The total width as well as the stiffness of the application also play a role and can negatively impact the load capacity and wear properties.

To reach the indicated nominal load FR, install the cam roller carriage so that the load is applied to the side with the greatest number of rollers. To prevent mix-ups, this is marked with two notches on the base body of the carriage.

The total load FG of the application must be transmitted to the cam roller carriages as centrally as possible. Sudden impacts and jolts as well as strong vibrations acting on the linear guide rail systems are to be avoided. The application or absorption of torque forces in the MX and MZ directions via to the cam roller carriages is not intended.

If higher loads are to be moved, this can be accomplished by using an additional support structure (in the FR direction) on the outside of the guide rail which allows additional cam roller carriages to be used. The support keeps the rail from spreading or slipping. However, functioning should be checked in a test set-up.

| h1 (construction height) | FR per cam roller carriage in N | FG resulting in N | MY per cam roller carriage in Nm | |

| with 2 cam roller carriages | with 4 cam roller carriages | |||

| 30 | 840 | 1680 | 3360 | 14 |

| 45 | 1690 | 3380 | 6760 | 35 |

The cam roller linear guide rails and cam roller carriages should be lightly lubricated on the running surfaces and with high performance roller bearing grease before initial use. The grease should be distributed evenly over the entire length of the rail using a paintbrush. In normal environments, Shell Gadus S2 V220 or Klüberplex BE 31-222, for example, can be used as a lubricant. In areas of application such as the food and pharmaceutical industry, use lubricants approved by the FDA. Examples are Klüberfood NH1 94-301 or Klübersynth UH1 14-151.

After 50 km, six months, or equivalent soiling or discoloration of the lubricant, the rails and cam roller carriages should be cleaned with a clean cloth and re-lubricated. If potential soiling is greater, the maintenance intervals should be shorter. Prevent soiling by providing suitable covering or optimum placement of the linear guide rail systems.

Stainless steel linear guide rail systems are preferably installed vertically, in pairs, with a horizontal alignment. This results in the highest possible stability and torsional stiffness in the smallest installation space. The running properties are optimal in this arrangement, and wear is reduced to a minimum.

In contrast to telescopic slides, linear guide rail systems can be used in a vertical orientation because no cage slip occurs since the design does not include a ball cage. It is only necessary to consider the direction in which the load acts so that the cam roller carriages can be inserted correctly into the guide rail.

The horizontal installation of the rail (lying down) is likewise possible with certain restrictions. The maximum load in this case is specified as the nominal load FA. Due to the unfavorable rail cross-section, larger forces can be expected to widen the rail, which may lead to a collision between the cam roller carriages and the heads of the mounting screws. In case of doubt, check the function under load in a test set-up.

| favorable | vertically, on both sides | |

| acceptable | vertically shifted, on both sides | vertically inclined, on both sides |

| unfavorable | vertically, on one side | horizontally, on one side |

- For applications in which there is a long travel path, rails with an overall length of 5200 mm are available upon request. Do not sequentially arrange several cam roller linear guide rails to achieve a longer travel path since the set play or preloading of the cam roller carriages cannot be kept constant over several rails.

- The guide rails can be cut to any length, if necessary. When sawing, care should be taken to not deform the profile cross-section. The use of a clamp is recommended. After cutting, the cut surfaces must be deburred and cleaned before lubricating the running surfaces.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.