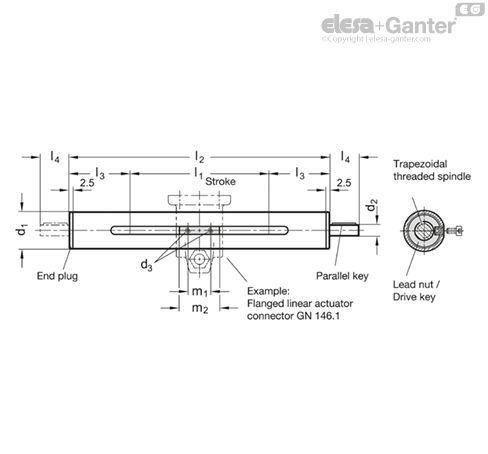

GN 291

Linear actuators

Steel / Stainless Steel, with right or left hand thread

GN 291

Linear actuators

Linear actuators

GN 291-SCR

Linear actuators

Steel, chrome-plated

GN 291

Linear actuators

Linear actuators

Types

- Type R1: Right hand thread, shaft journal at one end

- Type R2*: Right hand thread, shaft journal at both ends

- Type L1: Left hand thread, shaft journal at one end

- Type L2*: Left hand thread, shaft journal at both ends

* usually not available from stock

Guide tube

Version in Steel

Tube DIN 2391

Steel, chrome-plated SCR

Version in Stainless Steel*

Tube DIN 2462

Stainless Steel AISI 304 NI

* usually not available from stock

Spindle with trapezoidal thread

- Steel respectively, Stainless Steel AISI 303

- ball bearing

Lead nut

Gunmetal

End cap

Plastic

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.