GN 115.8

Hook-type latches

lockable / not lockable

GN 115.8-L

Hook-type latches

Lockable

GN 115.8-NL

Hook-type latches

Operation with socket key, not lockable

GN-115.8-NL

Hook-type latches

Operation with operating elements, not lockable

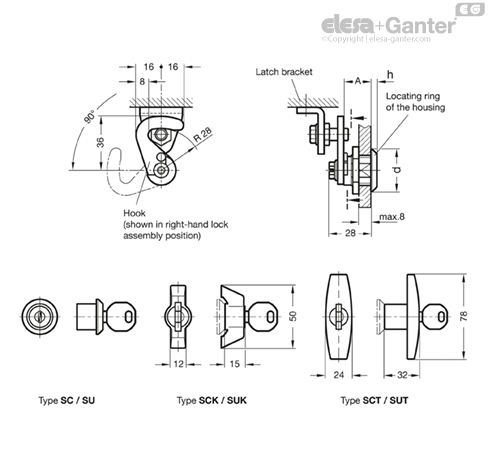

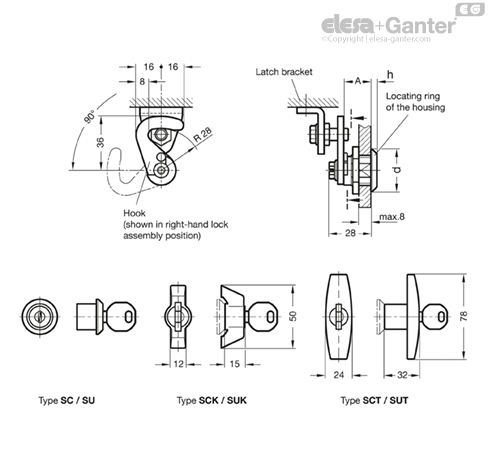

GN 115.8-L

Hook-type latches

Lockable

Lockable

Types

- Type SC: Operation with key (same lock)

- Type SU: Operation with key (different lock)

- Type SCK: Operation with wing knob (same lock)

- Type SUK: Operation with wing knob (different lock)

- Type SCT: Operation with T-Handle (same lock)

- Type SUT: Operation with T-Handle (different lock)

Version of the hook

Version H1: Pivot radius R=28

Identification no.

- No. 1: without latch bracket

- No. 2: with latch bracket

Lock housing

Zinc die casting

Locating ring

- chrome plated CR

- plastic coated, black, RAL 9005, textured finish SW

All other parts

Steel zinc plated, blue passivated

Key

Nickel silver with plastic hand piece

Wing knob / T-Handle

Plastic (Polyamide PA), black matt

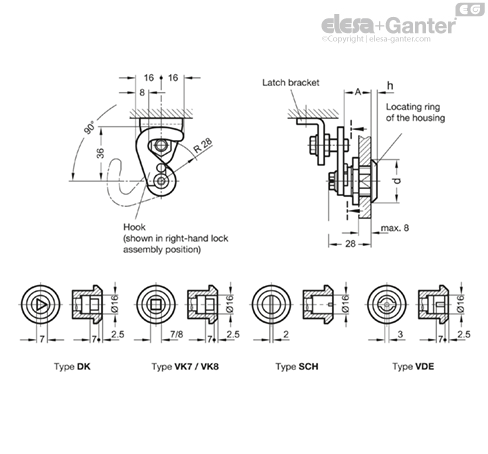

Operation with socket key, not lockable

Types

- Type DK: Operation with triangular spindle (DK7)

- Type VK7: Operation with square spindle A/F7

- Type VK8: Operation with square spindle A/F8

- Type SCH: Operation with slot

- Type VDE: Operation with double bit

Version of the hook

Version H1: Pivot radius R=28

Identification no.

- No. 1: without latch bracket

- No. 2: with latch bracket

Lock housing

Zinc die casting

Locating ring

- chrome plated CR

- plastic coated, black, RAL 9005, textured finish SW

All other parts

Steel zinc plated, blue passivated

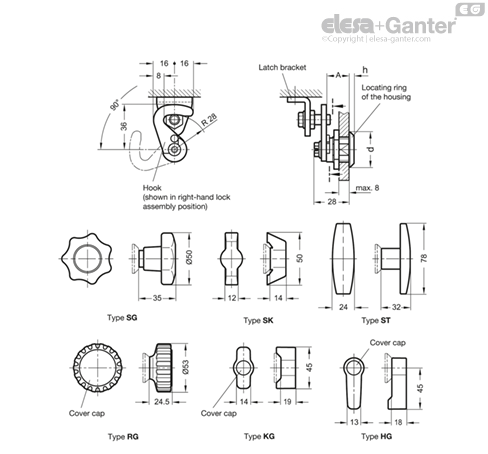

Operation with operating elements, not lockable

Types

- Type SG: Operation with star knob

- Type SK: Operation with wing knob

- Type ST: Operation with T-Handle

- Type RG: Operation with knurled knob GN 7336

- Type KG: Operation with wing knob

- Type HG: Operation with lever

Version of the hook

- Version H1: Pivot radius R=28

Identification no.

- No. 1: without latch bracket

- No. 2: with latch bracket

Lock housing

Zinc die casting

Locating ring

- chrome plated CR

- plastic coated, black, RAL 9005, textured finish SW

All other parts

Steel zinc plated, blue passivated

Operating elements

Plastic (Polyamide PA)

black, matt

Cover cap (type RG, KG, HG)

light grey

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.