GN 3975

Worm Gear Reducers

Housing Aluminum

GN 3975

Worm Gear Reducers

Worm Gear Reducers

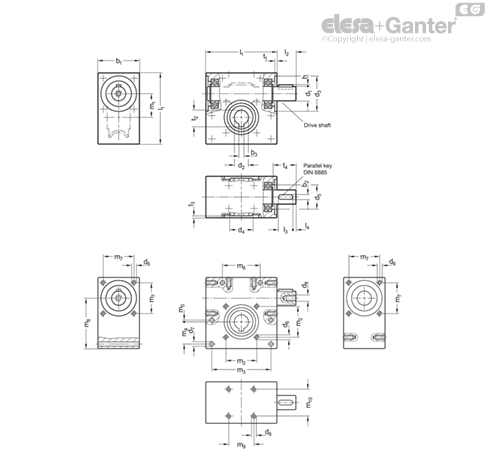

GN 3975-A

Worm Gear Reducers

One-side drive

GN 3975-B

Worm Gear Reducers

Continuous drive

GN 3975

Worm Gear Reducers

Worm Gear Reducers

Type

- Type A: Output on one side

Housing

- Aluminum

- Sealed to prevent dust entry

- Anodized, natural color AN

Worm screw, steel

Worm wheel, brass

Ball bearing

- Steel

- Sealed (sealing disks 2RS)

Temperature range: -20 °C to +60 °C

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.