CFM-TR-G

Hinges for mounting on glass or panels

SUPER-Technopolymer

CFM-TR-G

Hinges for mounting on glass or panels

Hinges for mounting on glass or panels

CFM-TR-G

Hinges for mounting on glass or panels

Hinges for mounting on glass or panels

Material

Glass-fibre reinforced polyamide based (PA) SUPER-technopolymer, black colour, matte finish.

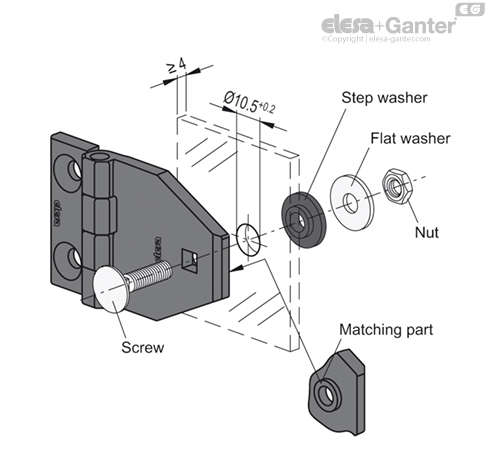

Flat washer

A4 UNI 6593-MT stainless steel.

Step washer

NBR rubber, hardness 70 Shore A.

Produced from FDA compliant raw material (FDA CFR.21 and EU 10/2011).

Rotating pin

AISI 303 stainless steel.

Standard execution

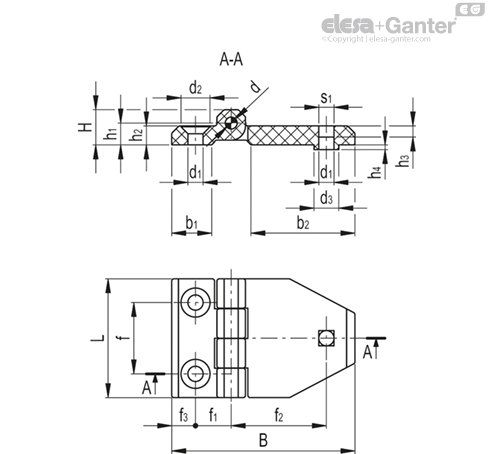

Frame side: pass-through holes for countersunk head screws.

Panel side: pass-through hole for round head square neck bolts according to UNI 5732 (choose the correct screw length depending on the thickness of the glass or of the panel).

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.