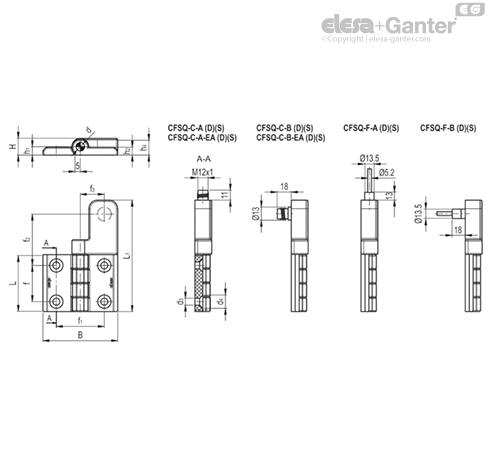

CFSQ.

Hinges with built-in safety switch

SUPER-technopolymer

CFSQ

Hinges with built-in safety switch

Hinges with built-in safety switch

CFSQ-C-A-D

Hinges with built-in safety switch

Axial connector, microswitch on the right

CFSQ-C-A-D-EA

Hinges with built-in safety switch

Axial connector, microswitch on the right

CFSQ-C-A-S

Hinges with built-in safety switch

Axial connector, microswitch on the left

CFSQ-C-A-S-EA

Hinges with built-in safety switch

Axial connector, microswitch on the left

CFSQ-C-B-D

Hinges with built-in safety switch

Rear connector, microswitch on the right

CFSQ-C-B-D-EA

Hinges with built-in safety switch

Rear connector, microswitch on the right

CFSQ-C-B-S

Hinges with built-in safety switch

Rear connector, microswitch on the left

CFSQ-C-B-S-EA

Hinges with built-in safety switch

Rear connector, microswitch on the left

CFSQ-F-A-D

Hinges with built-in safety switch

Axial cable, 2 or 5 m length, microswitch on the right

CFSQ-F-A-S

Hinges with built-in safety switch

Axial cable, 2 or 5 m length, microswitch on the left

CFSQ-F-B-D

Hinges with built-in safety switch

Rear cable, 2 or 5 m length, microswitch on the right

CFSQ-F-B-S

Hinges with built-in safety switch

Rear cable, 2 or 5 m length, microswitch on the left

CFSQ

Hinges with built-in safety switch

Hinges with built-in safety switch

Material

Self-extinguish high-rigidity SUPER-technopolymer, black colour, matte finish.

Thanks to its housing made out of SUPER-technopolymer, the CFSQ hinge guarantees the double insulation of the internal circuits, therefore there is no need of grounding connection. Furthermore, the housing protects the electric contacts from shocks, atmospheric agents and accidental penetration of tools.

Rotating pin

AISI 303 stainless steel.

Standard executions

Assembly by means of pass-through holes for M6 countersunk-head screws UNI 5933, DIN 7991.

Starting work angle 0°:

- C-A-D: axial connector, microswitch on the right.

- C-A-S: axial connector, microswitch on the left.

- C-B-D: rear connector, microswitch on the right.

- C-B-S: rear connector, microswitch on the left.

- F-A-D: axial cable, 2 or 5 m length, microswitch on the right.

- F-A-S: axial cable, 2 or 5 m length, microswitch on the left.

- F-B-D: rear cable, 2 or 5 m length, microswitch on the right.

- F-B-S: rear cable, 2 or 5 m length, microswitch on the left.

Starting work angle -90°:

- C-A-D-EA: axial connector, microswitch on the right.

- C-A-S-EA: axial connector, microswitch on the left.

- C-B-D-EA: rear connector, microswitch on the right.

- C-B-S-EA: rear connector, microswitch on the left.

Cable type: UL/CSA STYLE 2587 3 X AWG 22.

LOOKING FOR ALUMINIUM PROFILES:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.