STP - A new innovation in the Super-technopolymer range

The new STP threaded stems, designed for levelling equipment and machinery, are entirely made of SUPER-Technopolymer, a latest generation polymeric plastic material with high mechanical performance, excellent resistance to chemical agents, and optimum thermal properties.

Each material has its own unique properties and is chosen based on the application, the sector, and the operating and use conditions. The wide range of ELESA+GANTER levelling elements, in addition to this latest innovation, is made up of different combinations of materials, including:

- technopolymer base with zinc-plated steel or stainless-steel threaded stem, also with no-slip disk in NBR rubber or anti-vibration disc for vibration dampening;

- variants entirely made of zinc-plated steel;

- different AISI classes of stainless steel, including 316L for special applications;

- Hygienic Design levelling feet for use in environments where a certified level of hygiene is required.

Standard, but still high-performance!

The new STP stems, available in different lengths and with threads from M8 to M12, guarantee a maximum static load resistance ranging from 2700 N for the smallest sizes up to 7000 N for the largest.

The surprising mechanical resistance is accompanied by the numerous advantages typical of the SUPER-technopolymer category.

Let’s take a closer look at them:

- high mechanical resistance thanks to the presence of very high percentages of glass fibre bonded with appropriate chemical primers to the base polymer and/or the presence of synthetic aramid fibre;

- resistance to corrosion and to the most common chemical agents for applications that require frequent washing (food, pharmaceutical, medical, etc.) or for use in humid environments or outdoors, with excellent durability.

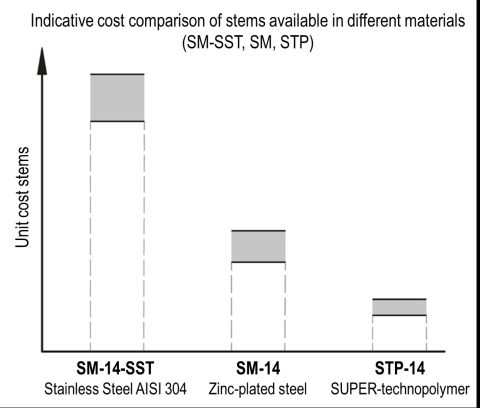

Figure 2 – Cost comparison with other stem materials

Figure 1 compares resistance to the most common chemical agents between the SUPER-Technopolymer, the zinc-plated steel and the stainless-steel versions. As can be seen in the detailed table, there are many more black marks (“suitable”) in the SUPER-Technopolymer material column;

- lightness which, in addition to making transport, storage and handling more economical, represents an advantage especially for those applications intended for mobile machines or equipment;

- a significant economic advantage compared to traditional stainless steel or zinc-plated steel solutions (Figure 2). The “y” axis shows how the range of unit costs, depending on the size, of the STP stems in SUPER-Technopolymer, for the same size of the ball joint (Ø 14), is far more cost-effective than the stainless-steel stems or even the zinc-plated steel stems.

More information on this Elesa+Ganter standard element can be found on OIC’s website by simply clicking here.