HVF-E

Ends and sensor holder

Polypropylene based (PP) technopolymer, black colour, matte finish.

Axis and rotor propeller

Polypropylene based (PP) technopolymer, red colour. AISI 304 stainless steel sensor activating clips.

Tubular window

Borosilicate glass, high-resistance, also suitable for use with glycol-based solutions.

Sensor

Nickel-plated brass inductive sensor

Tie rods

AISI 316L stainless steel.

Packing rings

NBR synthetic rubber.

Standard execution

Brass bosses with cylindrical gas thread according to UNI ISO 228/1.

Maximum continuous working temperature

100° C.

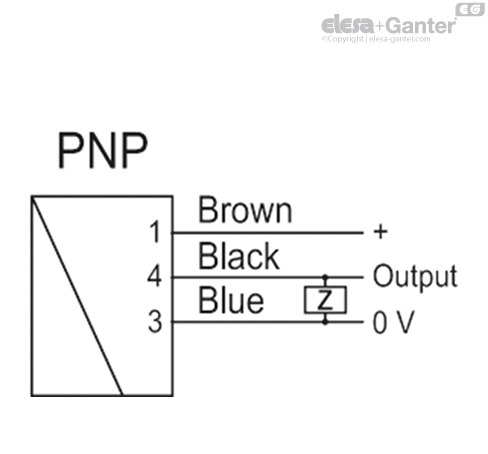

| Sensor | Inductive |

| Power supply | 10 – 30 Vcc |

| Input | 10 mA |

| Max load | 200 mA |

| Short circuit protection | Yes |

| Reverse polarity protection | Yes |

| Output | PNP |

| Connector | M12x1 – 4 poli |

| Protection class | IP67 |

LOOKING FOR SOMETHING:

Feeling overwhelmed with what product to choose?

Don’t delay, give OIC a call and talk to us about your industrial application. Our aim is to help your business choose the right Elesa+Ganter element for the function you need. Whether you need to clamp, close, connect, control, level, manoeuvre, measure or set. OIC has an Elesa+Ganter machine element to fit your need.

We want to find out about your industrial application need and where we can help. Our contact details are below.